Electronics Manufacturing fertigt elektronische Baugruppen mit den modernsten Methoden und unter Einhaltung höchster Qualitätsstandards.

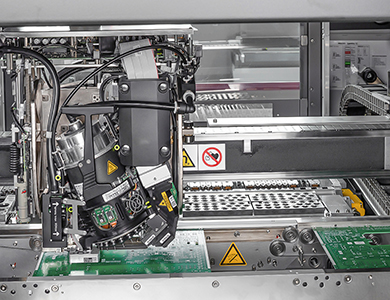

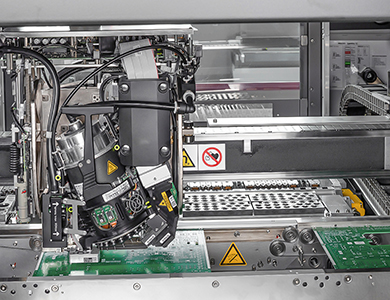

Unsere hochmodernen Bestückungslinien sind auf Präzision, Effizienz und Fehlervermeidung ausgerichtet.

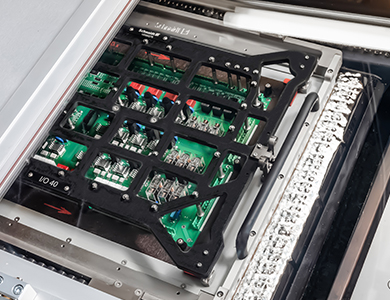

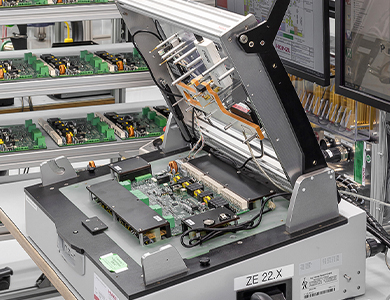

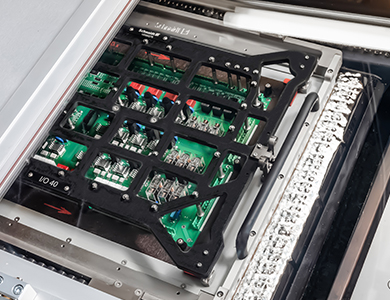

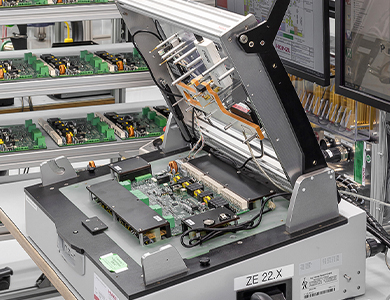

Mit einem projektindividuellen Prüfsystem oder einem Universaltest garantieren wir die gründliche und zuverlässige Qualitätskontrolle Ihrer Baugruppe.

Seit 40 Jahren fertigen wir dort elektronische Baugruppen mit modernsten Methoden und unter höchsten Qualitätsstandards.

Ein Team aus 70 Mitarbeiter:innen im Zwei- und Dreischichtbetrieb sorgt dafür, dass Ihre Platinen nach individuellen Projektanforderungen gefertigt werden – von der SMD- und THT-Bestückung über Funktionstests bis hin zu Schutzbeschichtung und Verpackung.

Auf mehr als 2.500 m² Produktionsfläche entstehen so jährlich unzählige Baugruppen für unterschiedlichste Branchen.

Smart zur Serie – made in Austria.

• Modernste Fertigungstechnologien für eine durchgängig hohe Qualität. Unsere hochmodernen Bestückungslinien sind auf Präzision und Fehlervermeidung ausgerichtet.

• Termintreue ist das Um und Auf. Wir setzen alles daran, Fertigungsabläufe so zu gestalten, dass Ihre Produkte rechtzeitig bei Ihnen sind.

• Bestückung in Österreich. Wir setzen ein klares Bekenntnis zur regionalen Elektronikfertigung. Die Bestückung Ihrer Leiterplatte erfolgt in Österreich.

• Lückenlose Traceability für mehr Transparenz: Durch die Rückverfolgbarkeit aller Rohmaterialien und Fertigungsschritte haben Sie als Kunde die Gewissheit, dass alle Komponenten und Materialien den höchsten Standards entsprechen und unsere Produktionsprozesse transparent und nachvollziehbar gestaltet sind.

Bei HAINZL Embedded Systems begleiten wir Sie von der Idee bis zum fertigen Produkt und entwickeln leistungsstarke Hard- und Software für Ihre Serie.