Are you looking for a customized testing solution for your applications? Contact us—our experts will be happy to assist you in developing your individual testing technology!

Testing hydrogen components Components for hydrogen applications require particularly reliable and safe testing and analysis.

With our high-precision hydrogen testing systems, we support our partners in developing safe and high-performance components for hydrogen applications, from the prototype phase to series production.

Our hydrogen testing systems enable the reliable development and testing of key components under realistic conditions:

// Electrolysis stacks

// Sensors

// Valves

// Pressure-retaining equipment parts

// Hydrogen tanks (e.g., type 4)

Wir bieten nicht nur einzelne Prüfstände, sondern komplette, integrierte Lösungen, die Montage und Prüfung in einem nahtlosen Prozess vereinen. Unsere Systeme kombinieren automatisierte Montagesysteme, Roboter und moderne Werkerführung mit präziser Prüfstandstechnik.

Diese Integration sorgt für fehlerfreie und effiziente Prozesse, hohe Qualität, vollständige Rückverfolgbarkeit und stabile Abläufe – für maximale Effizienz und Sicherheit in Ihrer Fertigung.

This PEM electrolysis stack test bench is used for the development and characterization of PEM electrolysis stacks with a maximum electrical power of 160 kW.

It offers maximum precision in the control and measurement of relevant parameters such as voltage, current, and temperature. All values are recorded with the highest accuracy and continuously monitored. Full automation enables complex tests and long-term measurements to be carried out.

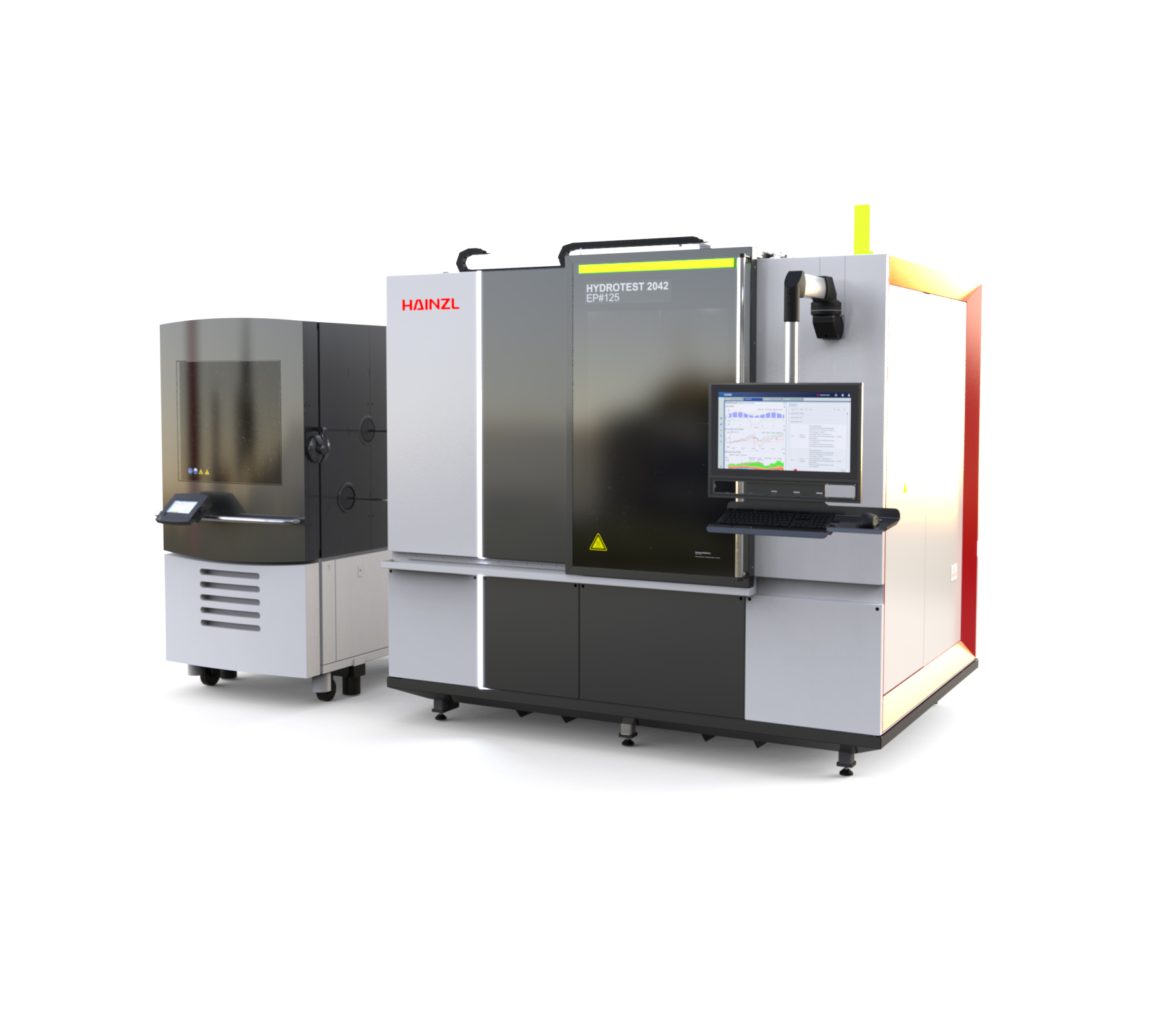

This test bench supports the development of pressure and shut-off valves for hydrogen fuel systems up to 700 bar.

An integrated valve system simulates realistic pressure fluctuations, while a heatable test chamber examines thermal influences on the test specimen.

The use of forming gas enables safe and cost-efficient operation without hazardous areas.

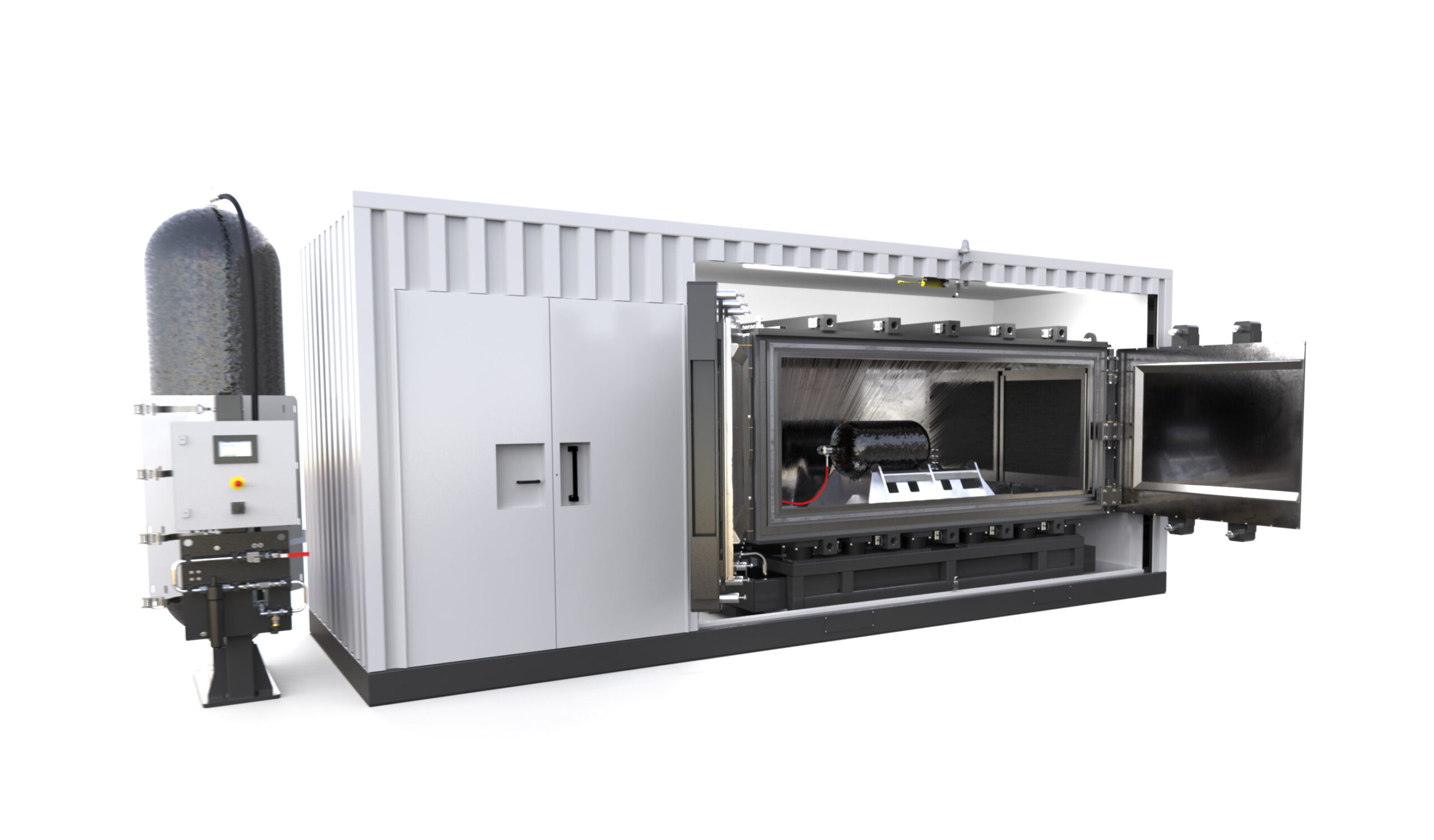

This test bench enables burst pressure testing of type 4 hydrogen tanks in accordance with ECE R134 and EC 79/2009.

The compact container design allows for easy handling of the test specimens by forklift and convenient cleaning after testing.

Thanks to its mobile design, the test bench can be used flexibly and also offers weather and sound protection.

Our development test stand was specially designed for the development and validation of sensors in a wide range of hydrogen applications. It automatically generates precisely defined gas mixture concentrations under variable pressure and temperature conditions in order to test sensor performance under realistic conditions.

The ATEX-compliant design also enables safe operation with pure hydrogen.

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.