Are you looking for a customized testing solution for your applications? Contact us—our experts will be happy to assist you in developing your individual testing technology!

Our specialized hydraulic test benches ensure the quality and performance of your hydraulic components, valves, pumps, and motors. Whether you need customized testing solutions or standardized test systems, we offer innovative technology for efficient and precise testing processes. Our test systems are easy to maintain, durable, and meet all applicable requirements of the European Machinery Directive.

For even more efficient use, we offer integration into our OCEAN automation platform, which enables seamless operation and evaluation of test results.

With OCEAN, you can monitor and evaluate test processes and receive automatically recorded data that helps you further optimize your production.

We are an established system supplier and partner for the following industries:

// Manufacturers of hydraulic components (OEMs)

// Aerospace

// Construction machinery

// Agricultural machinery

We offer not only individual test benches, but also complete, integrated solutions that combine assembly and testing in a seamless process. Our systems combine automated assembly systems, robots, and modern worker guidance with precise test bench technology.

This integration ensures error-free and efficient processes, high quality, complete traceability, and stable operations—for maximum efficiency and safety in your production.

We offer not only individual test benches, but also complete, integrated solutions that combine assembly and testing in a seamless process. Our systems combine automated assembly systems, robots, and modern worker guidance with precise test bench technology.

This integration ensures error-free and efficient processes, high quality, complete traceability, and stable operations—for maximum efficiency and safety in your production.

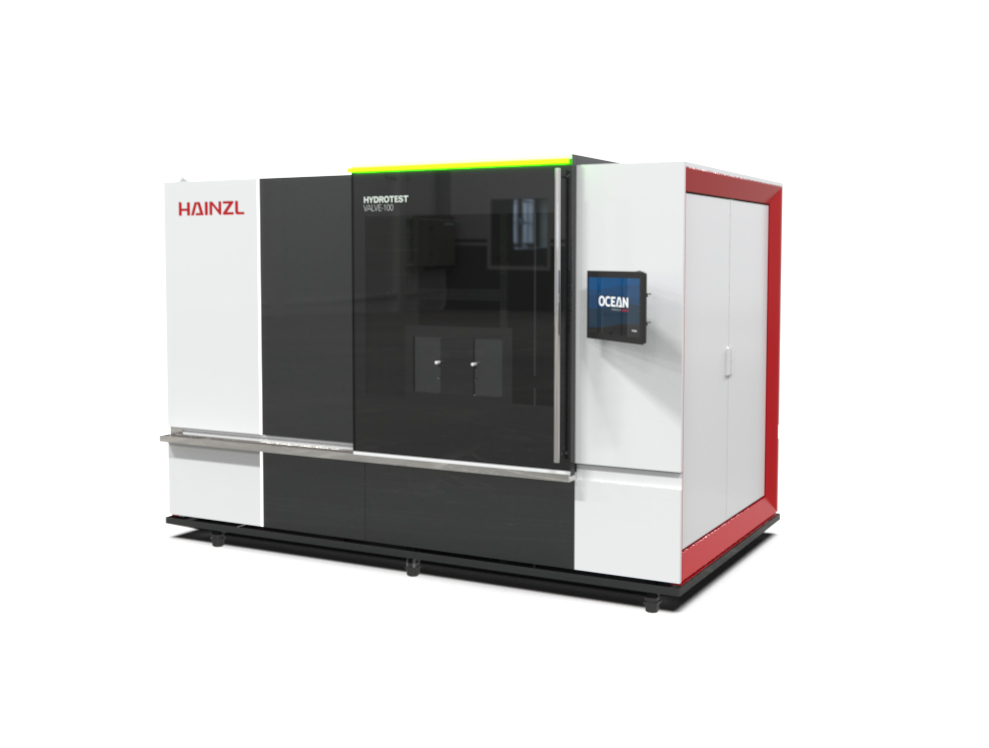

Our test benches for hydraulic valves are designed for use in end-of-line tests, development tests, and service applications. They enable the automated performance of pressure, leak, and endurance tests as well as performance tests. In addition, characteristic curves for pressure and flow can be run and volume flow settings can be made precisely.

// Automated test sequences for pressure, leak, and performance tests

// Safety enclosure of the test cell in accordance with the Machinery Directive and CE conformity

// Flexible adaptation for different valve types and customer-specific test parameters

// Testing in accordance with ISO 10770

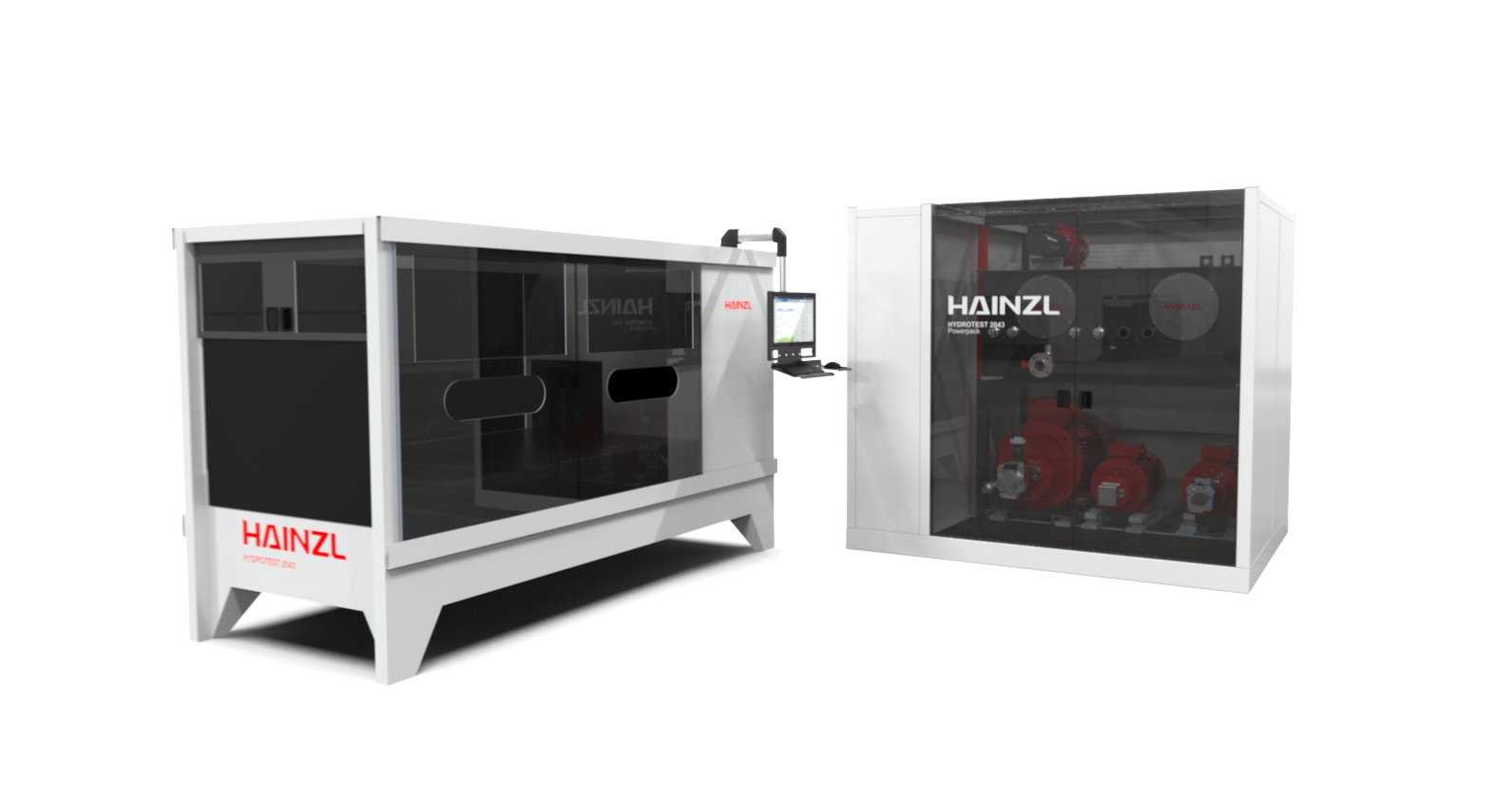

Our test benches offer a reliable solution for testing hydraulic pumps and motors. They enable precise tests such as run-in procedures, performance tests with load simulation and efficiency verification, suction pressure control, leakage testing, and the inspection and adjustment of controllers. In addition, high-pressure tests can be performed, and pumps with hydraulic adjustment can be precisely controlled.

Continuous monitoring of oil level, filter condition, and temperature, as well as a safe test cell, ensure maximum safety. In addition, we offer integration into our OCEAN automation platform, which enables seamless operation and efficient evaluation of test results. Our test systems are particularly suitable for:

// Hydraulic pumps and motors

// Gear pumps and motors

// Screw pumps

// Piston pumps and motors (axial, radial, reciprocating piston pumps)

// Vane pumps and motors

// Orbital motors

// Gerotor

Our hydraulic testing systems are ideal for reliably testing a wide variety of hydraulic components. They offer solutions for testing hoses, compensators, fittings, filters, heat exchangers, and sensors. Our systems enable precise tests to be carried out efficiently:

// Pressure tests (burst pressure/vacuum)

// Leak tests

// Endurance tests

// Performance tests

// Recording of pressure/flow characteristics

// Volume flow settings

Our systems guarantee maximum safety through continuous monitoring of oil level, filter condition, and temperature, as well as a secure test cell.

Our universal test benches offer a flexible solution for testing hydraulic components and systems, including cylinders, valves, and specialized components. Different components can be tested using a single test bench.

The systems enable a wide range of tests, such as functional tests, leakage tests, static pressure tests (up to 400 bar), high-pressure tests (up to 700 bar), friction tests, and oil temperature measurements. External testing options are available for special cylinders.

The automation continuously monitors important system data such as oil level, filter condition, and temperature, ensuring maximum safety and efficiency. In addition, the systems are equipped with an oil pan for automated return transport. For large cylinders, an external mounting device offers maximum flexibility. The closed test cell reliably protects the operator from escaping media and meets the highest safety standards.

// Wide range of applications for cylinders, valves, and special components

// Automated test sequences for pressure, leakage, and friction tests

// Safety concept with closed test cell and continuous system monitoring

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.