Hydrogen is a key factor for a sustainable future in industry, energy, and mobility. As experts in handling hydrogen, we develop systems to advance the hydrogen economy. In doing so, we make an important contribution to a climate-neutral energy system of the future and ensure that hydrogen technology is efficient and widely available.

Our system solutions cover the entire hydrogen supply chain:

// Hydrogen production: PEM electrolysis as an immediate solution, AEM electrolysis as a promising approach for the future

// Hydrogen infrastructure: compression, storage, and filling of hydrogen

// Hydrogen testing systems for all H2 components

As a comprehensive system partner and general contractor in the field of hydrogen, we support our partners

in the realization of their hydrogen projects. As a specialist in the field of test benches and test systems,

we offer the necessary expertise for the development and testing of hydrogen components such as sensors, valves, and stacks.

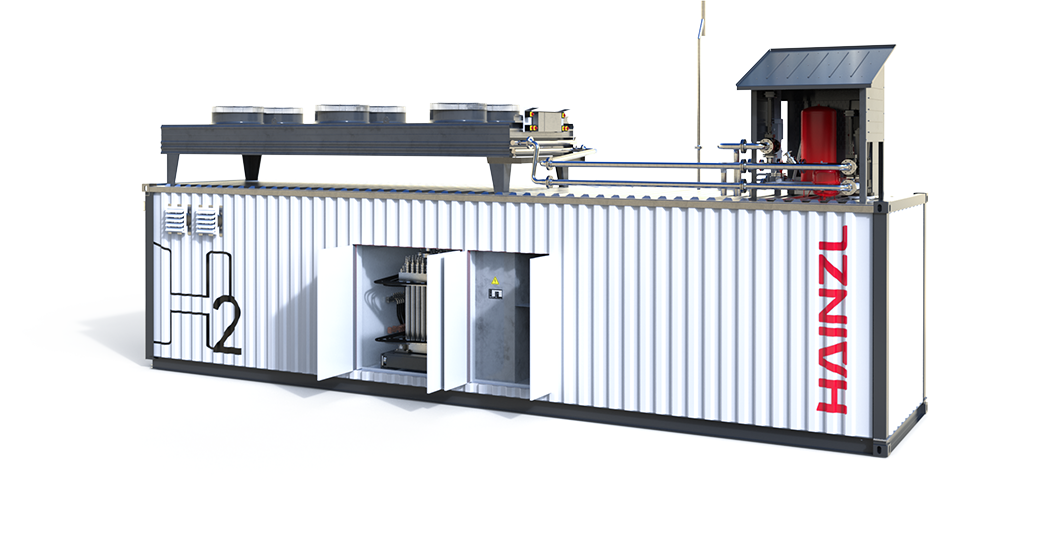

HAINZL has developed an innovative container-based electrolysis system for the sustainable production of hydrogen.

The HAINZL PEM electrolyzer is the turnkey solution for producing green hydrogen. The modular system allows for efficient scalability to the desired size of the customer's project.

// Scalable plug-and-play solution from 1 MW

// Dynamic operation from 10 to 100%

// Compact and modular design

// Flexibility for different applications

// Independent automatic operation with remote maintenance

Optional features:

// Waste heat extraction

// Oxygen utilization

// AEM-ready

HAINZL has developed an innovative container-based electrolysis system for the sustainable production of hydrogen.

The HAINZL PEM electrolyzer is the turnkey solution for producing green hydrogen. The modular system allows for efficient scalability to the desired size of the customer's project.

// Scalable plug-and-play solution from 1 MW output

// Dynamic operation from 10 to 100%

// Compact and modular design

// Flexibility for different applications

// Independent automatic operation with remote maintenance

Optional features:

// Waste heat extraction

// Oxygen utilization

// AEM-ready

Electrolysis uses electricity to split water into its components hydrogen (H₂) and oxygen (O₂). If electricity from renewable sources is used for this purpose, green hydrogen is produced—a climate-friendly energy source of the future.

HAINZL relies on PEM technology in a compact container solution. The system covers all steps—from water treatment and electrolysis to purification of the hydrogen produced. This creates a ready-to-use, high-purity energy source for industry, mobility, or energy storage. Looking to the future, HAINZL is also exploring other innovative technologies such as AEM electrolysis.

Electrolysis uses electricity to split water into its components hydrogen (H₂) and oxygen (O₂). If electricity from renewable sources is used for this purpose, green hydrogen is produced—a climate-friendly energy source of the future.

HAINZL relies on PEM technology in a compact container solution. The system covers all steps—from water treatment and electrolysis to purification of the hydrogen produced. This creates a ready-to-use, high-purity energy source for industry, mobility, or energy storage. Looking to the future, HAINZL is also exploring other innovative technologies such as AEM electrolysis.

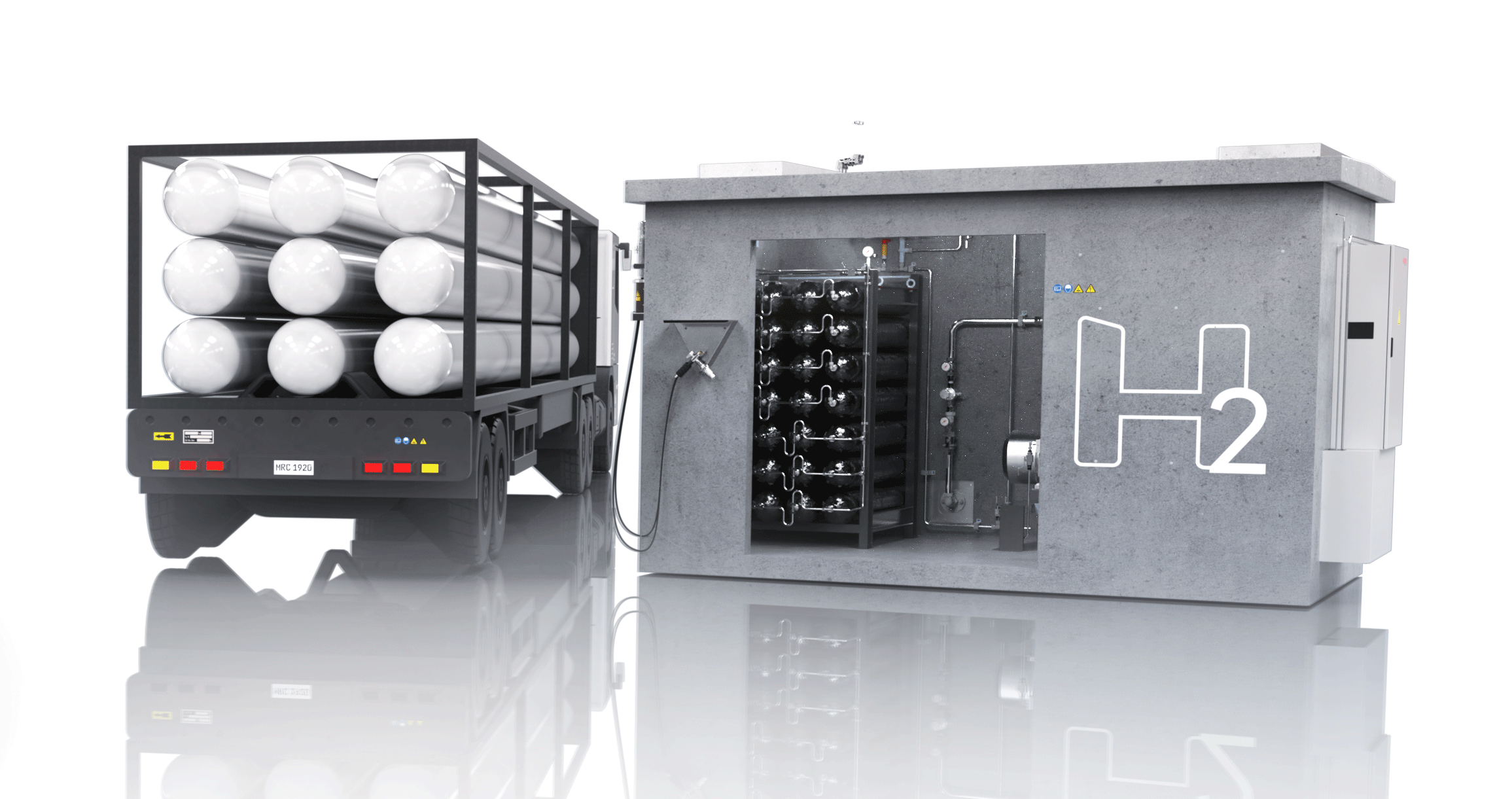

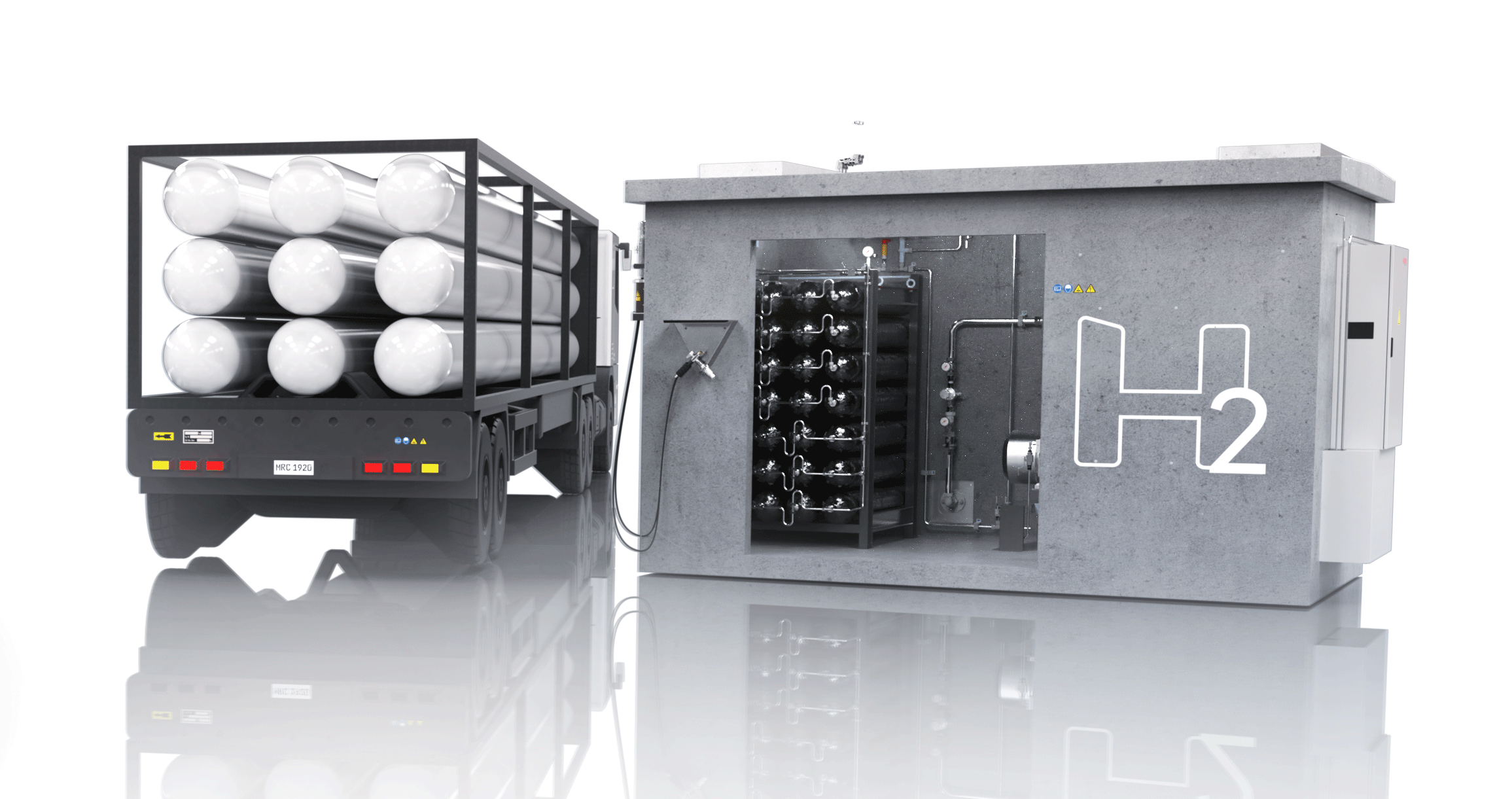

Together with our partners, we develop efficient and safe hydrogen systems. We offer system solutions for compressing gaseous hydrogen to over 1000 bar and for safe distribution from the source to the point of use.

Our products:

// H2 filling stations (e.g., trailers or cylinders)

// Hydrogen distribution systems (e.g., hydrogen networks)

// H2 refueling stations (e.g., for refueling commercial vehicles)

// H2 compressor stations for hydrogen storage

Together with our partners, we develop efficient and safe hydrogen systems. We offer system solutions for compressing gaseous hydrogen to over 1000 bar and for safe distribution from the source to the point of use.

Our products:

// H2 filling stations (e.g., trailers or cylinders)

// Hydrogen distribution systems (e.g., hydrogen networks)

// H2 refueling stations (e.g., for refueling commercial vehicles)

// H2 compressor stations for hydrogen storage

Components for hydrogen applications require particularly reliable and safe testing and analysis.

With our high-precision hydrogen testing systems, we support our partners in developing safe and high-performance components for hydrogen applications, from the prototype phase to series production.

Our hydrogen testing systems enable the reliable development and testing of key components under realistic conditions:

// Sensors

// Valves

// Pressure-retaining equipment parts

// Hydrogen tanks (e.g., Type 4)

// Burst testing

// Pressure testing

// Pressure cycle testing

// Leak testing in accordance with ECE_R134

// Electrolysis stacks

// PEM electrolysis stacks up to 1.5 MW

// AEM electrolysis stacks up to 150 kW

Components for hydrogen applications require particularly reliable and safe testing and analysis.

With our high-precision hydrogen testing systems, we support our partners in developing safe and high-performance components for hydrogen applications, from the prototype phase to series production.

Our hydrogen testing systems enable the reliable development and testing of key components under realistic conditions:

// Sensors

// Valves

// Pressure-retaining equipment parts

// Hydrogen tanks (e.g., Type 4)

// Burst testing

// Pressure testing

// Pressure cycle testing

// Leak testing in accordance with ECE_R134

// Electrolysis stacks

// PEM electrolysis stacks up to 1.5 MW

// AEM electrolysis stacks up to 150 kW

Our products, machines and systems are as versatile as we are. Our heart beats for mechatronics, from compact and reliable to complex and energy-efficient.

Are you planning a hydrogen project? Contact us—we can support you with customized system solutions along the entire supply chain.

In order to store large quantities of gaseous hydrogen efficiently, it must first be compressed. HAINZL's compression systems compress hydrogen to all common pressure ranges.

Our hydrogen compression systems can be used for low, medium, and high pressure ranges. We cover all pressure levels up to 1000 bar. The higher the pressure, the less space is required for storage.

In order to store large quantities of gaseous hydrogen efficiently, it must first be compressed. HAINZL's compression systems compress hydrogen to all common pressure ranges.

Our hydrogen compression systems can be used for low, medium, and high pressure ranges. We cover all pressure levels up to 1000 bar. The higher the pressure, the less space is required for storage.

Our storage systems enable the safe and efficient storage of hydrogen – for all pressure levels up to 1000 bar.

In the low-pressure range, large storage volumes are necessary due to the physical properties of hydrogen.

The advantage of high-pressure storage is the significantly reduced space requirement per kilogram of hydrogen stored. The diverse applications of hydrogen require a wide range of pressure levels (e.g., 50, 300, 500, or 1000 bar). HAINZL's solutions cover all required pressure levels.

Our storage systems enable the safe and efficient storage of hydrogen – for all pressure levels up to 1000 bar.

In the low-pressure range, large storage volumes are necessary due to the physical properties of hydrogen.

The advantage of high-pressure storage is the significantly reduced space requirement per kilogram of hydrogen stored. The diverse applications of hydrogen require a wide range of pressure levels (e.g., 50, 300, 500, or 1000 bar). HAINZL's solutions cover all required pressure levels.

HAINZL filling systems are used to fill hydrogen trailers with the hydrogen produced and to refuel hydrogen vehicles.

Our trailer filling systems enable trailers to be filled with different filling pressures up to 500 bar.

Our refueling systems enable the safe filling of hydrogen-powered vehicles, regardless of whether they are passenger cars or commercial vehicles. Our solutions are designed for pressures of 350 and 700 bar.

HAINZL filling systems are used to fill hydrogen trailers with the hydrogen produced and to refuel hydrogen vehicles.

Our trailer filling systems enable trailers to be filled at different filling pressures up to 500 bar.

Our refueling systems enable the safe filling of hydrogen-powered vehicles, regardless of whether they are passenger cars or commercial vehicles. Our solutions are designed for pressures of 350 and 700 bar.